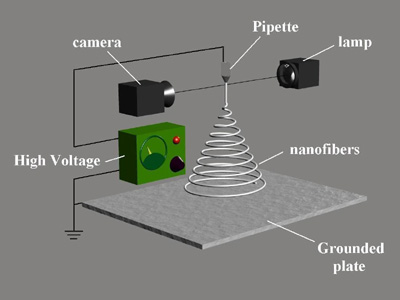

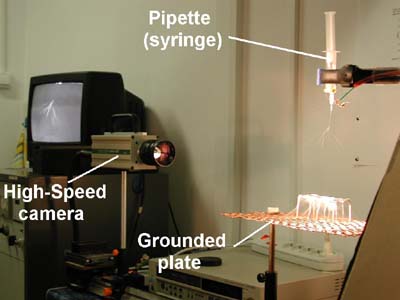

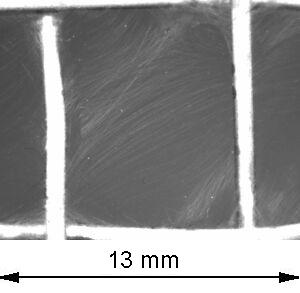

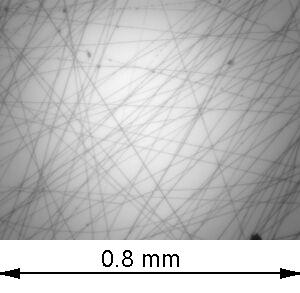

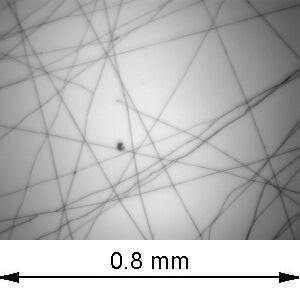

Electrospinning is a straightforward method that produces polymer nanofibers*. When the electrical force at the surface of a polymer solution or polymer melt overcomes the surface tension, a charged jets is ejected. The jet extends in a straight line for a certain distance, and then bends and follows a looping and spiraling path. The electrical forces elongate the jet thousands or even millions of times and the jet becomes very thin. Ultimately the solvent evaporates, or the melt solidifies. The resulting, very long, nanofiber collets on an electrically grounded metal sheet.

* H.Fong, D.H.Reneker "Electrospinning

and the Formation of Nanofibers"

|